BudinGroup And Teksmer Are Spinning The Recycling Wheel.

“Recycled and Functional Bicomponent Fibers” Bringing to Economy With Zero Waste Project

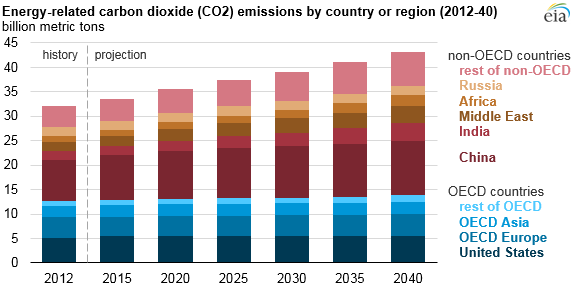

The radical decarbonisation promises of the USA and European Union countries, especially China, which pollutes the world the most with 10.5 billion tons of carbon dioxide emission annually, have brought a wide-ranging dimension to the fight against the climate crisis, which will also affect trade.

World trade is about to enter a process that depends on ecological standards, where every country cannot produce industry as they wish. Textile, which accounts for 7 percent of global emissions, is one of the most prominent sectors as the world’s second largest pollutant.

In cooperation with BUDIN Chemical Materials Industry and Trade Limited Company – Technical Textiles Research and Application Center (TEKSMER), UV resistant Bicomponent textile fibers were developed by using recycled polymers.

Aegean Exporters Union Coordinator Chairman Jake Ashkenazic, Turkey’s textile in the world that takes place among the leading manufacturers in the industry in the country, even even if not directly told to agriculture, and also that the effect largely to the industry.

“We have sought ways to transform the technical textile industry, which has a rapidly growing 107 billion dollar export market, into a new, low-carbon system by investing in R&D and innovation.

2014 Aegean Textile and Raw Materials Exporters ‘Association Aegean Clothing and Apparel Exporters’ Association and Dokuz Eylul University’s partnership in İzmir Development Agency was established as a targeted projects, Turkey’s first technical textile center Teks, throwing many projects in decades in sustainable industries . In order to develop new generation fibers and fibers, which are the basic raw materials of technical textiles, it has recently accelerated its work and added a new one to its success.

In cooperation with BUDIN Chemical Materials Industry and Trade Limited Company – TEKSMER, functional bicomponent textile fibers were developed by recycling the wastes generated after production.

We will open up to the world market with our fabric produced from recycled fibers, which we developed by further advancing our project supported by the European Bank for Reconstruction and Development.

Every country will have a carbon footprint: Climate negotiations must begin

Jake Ashkenazic, Turkey’s remarks, saying that the two countries showed the highest increase among OECD countries, the rate of increase in carbon emissions continued as follows:

“This rate of increase may highlight us as one of the major pollutants until 2030. A period in which each country will have a carbon footprint awaits us.

Climate change should be included in our industrial strategy, in our medium and long-term development plans. We know the solutions. We have the power to change. So what are we waiting for? Negotiations on solutions for the climate should begin as soon as possible.

We should have brands that produce in accordance with new conditions, provide added value, create employment, and whose products are sought in the world. In this way, we can obtain a national wealth that can compete in the green new order and create added value. This is the correct way to change the axis. ”

Technical textile exports reached 2.6 billion dollars

Turkey’s technical textile exports in the January-November period, 68 per cent increased 2.6 billion dollars that describes TEKS President Sabri Board Unluturk, increasing by 91 percent the technical textile exports to the Aegean Region was mentioned that carry 174 million dollars.

“Turkey general technical textile exports has featured 10 countries; USA, Germany, UK, Italy, Netherlands, Spain, Romania, France, Poland and Egypt. In our technical textile exports from the Aegean, China ranks first.

We are expanding our value added chain and trade channel with a new generation of production that produces innovative and sustainable solutions. Design of fabrics with low fiber release is one of our primary goals. Because the circular economy is a process that starts at the idea stage and continues from the cradle to the grave. If we dream of a zero waste-free industry, we must carry out the process by planning every point from the design stage to the production stage of the produced material. With our years of work, we have witnessed how the industry can adapt to and change the circular economy with recycling.

World Economic Forum or the cause of fighting climate failing to reach quick results of the G20 summit not to the exclusion of smaller countries such as Turkey, Russia, Saudi Arabia, Indonesia, is the inclusion of real big countries such as Bangladesh. It’s time to be united. ”

The statement made by the project stakeholders about the project is as follows;

“BUDIN Chemical Materials Industry and Trade Limited Company – in cooperation with Teksmer; We are a member of Turkey Cyclic Economy Platform ‘The Circular Vouchers’ taking advantage of the technical assistance program, masterbatch production after reaction with the functional textile fibers of waste generated “zero waste” Our projects carried out on the target has been completed successfully.

“BUDIN Chemical Materials Industry and Trade Limited Company and Teksmer Eğitim Danışmanlık Araştırma ve Laboratuvar Hizmetleri A.Ş., which is designated as the consultant firm by EBRD (European Bank for Reconstruction and Development), for this project. A grant of € 19.000,00 was received for the study carried out with the company.

Bicomponent fibers were obtained from masterbatch wastes in the bicomponent fiber drafting system in Teksmer. With this system, which allows the use of two different types of masterbatches at the same time, studies have been carried out on the production and development of antistatic and UV resistant bicomponent textile fibers with the use of recycled polymers.

The joint work of Teksmer and BUDIN Chemical Materials Industry and Trade Limited Company on research and development to produce prototype products from recycled bicomponent fiber will continue.

BUDIN Chemical Materials Industry and Trade Limited Company , in the national and international textile industry for mass production will be able to work with proven manufacturers such as textile fiber and yarn manufacturing company in Turkey. Many companies working in the field of knitting and apparel and Teksmer have partnerships and studies will be carried out on surface yield. It is inevitable that “functional and recycled textile fabric” developed with these project studies will enter mass production and commercialization with the manufacturers in our country. ”