Packaging is a quality indicator for products. Many consumers choose products according to the appearance of the packaging. The quality and appearance of the packaging has a direct impact on the consumer’s purchasing decision. Manufacturers use their packaging as a marketing and communication tool. Customised packaging is becoming an important tool to reach end users by making a product stand out on the shelf. At this point, our visual lacquers come to the fore. Our two-component matt lacquer product has high chemical and mechanical properties such as water, moisture, solvent and scratch resistance while providing visual effect with its mattness. Especially in partial prints, packaging designs with matt and glossy prints at the same time attract attention.

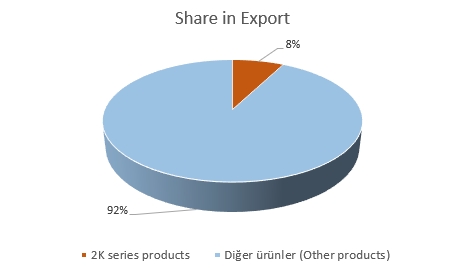

Our product, which is a Tübitak project output, has a high market share in exports (Figure 1). Another one of our visual effect lacquers is a two-component paper effect lacquer. This lacquer increases the attractiveness of the products with both visual and tactile effect. Again, like other two-component products, it has high chemical and mechanical properties. Paper effect lacquer is used in the packaging of natural and healthy products such as granola, nuts and dried fruits.

Our two-component products contain ester derivative solvents and can work mainly with rotogravure printing system. The first component lacquer and the second component isocyanate derivative hardener are mixed in the ratios specified in the technical data sheets. It can be applied on polyethylene LDPE-HDPE, BOPP and PET films. Printed films gain chemical and mechanical strength after curing for 3-4 days. For more information about our two-component FSP-2K- series, please contact us.